All you may need to know about concrete slump test: What differentiate the engineer from others on the project land is that he knows the exact specifications and appropriate standards for everything, and therefore he performs several tests in order to ensure the accuracy of the work. We have to take care of the concrete when it is soft, and also care must be taken when choosing its components, mixing and pouring it at the Facility. for example: The resistance of concrete and water is an inverse relationship, as the higher the percentage of water, the lower the concrete resistance and the higher the degree of operation.

Therefore, in this article, we will present to you how the process of controlling the quality of concrete is in the soft state, and then we will learn about one of the ways to test the quality of concrete, which is the fresh concrete drop test, and we will explain the method of work and the results that will appear with us, and analyze these results to show us the specifications of concrete precisely.

Quality Control of Fresh Concrete:

The following conditions must be met in soft concrete in order to obtain solid concrete of high quality and resistance:

- The soft concrete is easy to mix and transport.

- Ease of pouring and tamping of soft concrete without using additional effort.

- The aggregate granules should not separate during concrete pouring and condensation.

- Concrete should be homogeneous.

Fresh concrete drop test

First: an overview of this test

This test is considered the oldest and most widely used in all parts of the world, according to the specifications. This test is done through a simple device that contains an imperfect cone mold, with standard dimensions (small base of the cone 100 – large base of the cone 200 – cone height 300) mm.

Second: the way it works

- The mold is filled with fresh concrete on three layers of equal size.

- Each layer is compacted 25 times with an iron rod, having a diameter of 16 mm and rounded at its end.

- The surface of the cone is well leveled.

- The mold is lifted vertically directly.

- The amount of concrete slump is measured directly in millimeters, and the slump is the difference between the height of the concrete after landing and the height of the cone.

Third: Analyze the results

Three different types of subsidence can occur depending on the concrete mix.

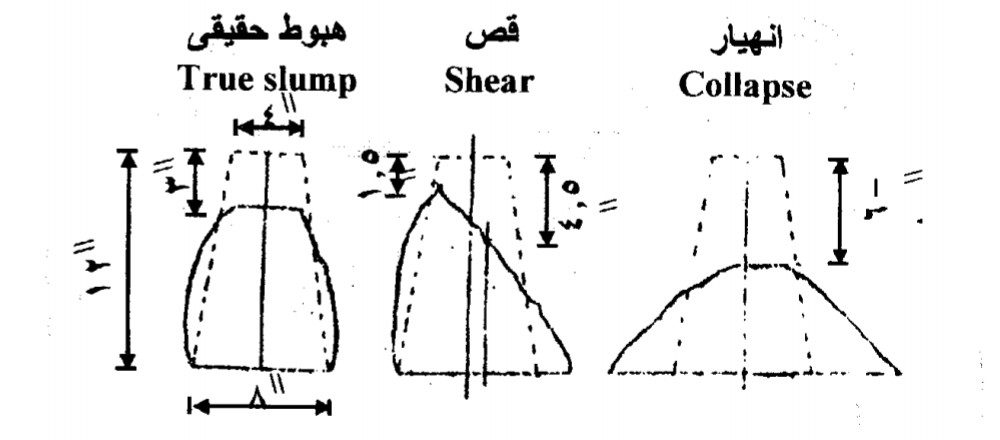

As we can see in the following picture, there are three types of subsidence, and from the shape of the drop, we can determine the specifications of concrete.

- In the event of a shear drop, the test must be repeated. This type of drop indicates that the concrete is dry with the possibility of indicating a loss of cohesion.

- In the case of the collapse of the collapse, this usually indicates two things, either that the concrete is very wet or the concrete is poor.

This test is very useful in construction projects sites, and gives a clear idea of whether the concrete is organized and homogeneous or not, but as we mentioned earlier, it is not recommended to use this test for dry concrete, not even for very wet concrete, because in these cases the test does not give an accurate value in both cases