Super Pave Mix Design Method

Standards:

AASHTO R 28 ASTM D 4402

EN 13302 ASTM D2196 AASHTO T316 ASTM D44022

ASTM D4402 AASHTO M320-10 AASHTO T315-12 AASHTO M332-14 AASHTO T350-14 AASHTO TP 70 ASTM D7405-10A EN 14770 ASTM D7175-08 ASTM D4402 M

AASHTO T 240 and ASTM D 2872

ASTM D6648 AASHTO T313 EN 14771

EN 12697-26 ANNEX E EN 12697-26 ANNEX D AASHTO TP 107-14

What is super pave?

In the 1980s, many state transportation departments were experiencing widespread premature deterioration of asphalt pavements. To address this problem the Strategic Highway Research Program (SHRP) undertook a program of asphalt research that eventually led to a new asphalt mixture design and analysis system called Super pave. Super pave stands for Superior Performing Asphalt Pavements.

The Super pave system includes a performance-based asphalt binder specification, a mix design analysis system, many new test procedures, and new equipment. The Strategic Highway Research Program was established by Congress in 1987 as a five (5) year, $150-million research program to improve the performance and durability of our highway system.

In 1991, Congress authorized The Federal Highway Administration (FHWA) to initiate full-scale implementation of Superpave and other SHRP research results. This process began in 1993 when SHRP delivered its final research findings. States, FHWA, and industry all took advantage of techniques such as state pooled-fund equipment buys, expert task groups, mobile laboratories, user-producer group, the American Association of State Highway and Transportation Officials (AASHTO) Lead States Program, and Super pave Centers to implement the research results.

Super pave is a comprehensive system for the design of paving mixes that are tailored to the unique performance requirements dictated by the traffic, environment (climate), and structural section at a pavement site. It enhances pavement performance through the selection and combination of the most suitable asphalt binder and aggregate.

Super pave represents the integration of several products of the SHRP asphalt research program into a single system for the design and analysis of paving mixes. It encompasses new material specifications, test methods, equipment, software, and mixture design method.

A) Limitations on Current AC Physical Tests & Specifications

- Empirical and not performance-based.

- Not representative for the wide range of climatic conditions (low temperatures).

- Long-term aging is not considered.

- Same asphalt cement grade can behave differently in the field.

- Modified asphalt binders are not considered.

B) Superior Performing Asphalt Pavements (Super Pave)

- Super Pave is the result of the 5-year SHRP (Strategic Highway Research Program) that was launched in 1987.

- $50-million research effort.

- To develop performance-based tests and specifications for asphalt binders and HMA mixtures.

C) Super Pave Binder Tests & Specification Features

- Modified & unmodified asphalt binders are considered.

- Performance-based tests.

- Asphalt binder is tested at its three critical stages: i. Unaged ii. Short-term aging iii. Long-term aging

- The entire range of pavement temperatures is considered.

- Can control three specific types of HMA pavement distresses:

- a) Rutting b) Fatigue cracking c) Thermal cracking

- Test procedures and specifications were developed in SI units

D) Super Pave Physical Tests for Asphalt Binders

- Rolling Thin Film Oven (RTFO)

- Pressure Aging Vessel (PAV)

- Rotational Viscometer (RV)

- Dynamic Shear Rheometer (DSR)

- Bending Beam Rheometer (BBR)

- Direct Tension Tester (DTT)

1. Pressure Aging Vessel (PAV) AASHTO R 28

- Pressure Aging Vessel (PAV) AASHTO R 28

a) Heat RTFO aged asphalt binder until fluid enough to pour. Stir sample and pour 50 g into a preheated sample pan.

b) Place pans in a pan holder and place inside preheated PAV.

c) Seal the PAV and allow it to return to the aging temperature. What temperature? (90, 100, 110 °C) (194, 212, 230 °F)

d) Once the PAV has reached the desired temperature, pressurize the PAV to 300 psi (2.07 MPa) and maintain the pressure for 20 hours.

e) Gradually release the pressure and remove the pans from the PAV.

f) Place the pans in an oven set at 325°F (163°C) for 15 minutes, then scrape into a single container sized so that the depth of the residue in the container is between 0.55 and 1.57 inches (14 and 40 mm).

g) Degas the sample in a vacuum to remove entrapped air.

h) Store for use in physical property tests.

Pressure Aging Vessel (PAV) AASHTO R 28

▪ Short-term aging:

manufacturing, mixing, placement, and compaction ~

volatilization (primary) & oxidation (secondary)

▪ Long-term aging:

in-service ~ oxidation (primary)

▪ Aging temperature is based on the climate where the material is expected to be used.

➢ For cold climates, the PAV is performed at 194°F (90°C).

➢ For moderate climates, the PAV is performed at 212°F (100°C).

➢ For desert climates, it is recommended to perform the PAV at 230°F (110°C).

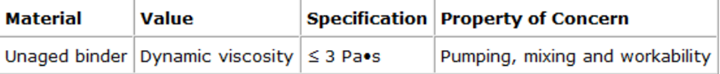

2. Rotational Viscometer (RV) ASTM D 4402

EN 13302 ASTM D2196 AASHTO T316 ASTM D44022

The Rotational Viscometer (RV) is used to determine the viscosity of asphalt binders in the high temperature range of production (manufacturing) and construction (mixing, placement and compaction). The RV test is always conducted at 275°F (135°C).

a) Preheat spindle, sample chamber, and viscometer environmental chamber (Thermosel) to 275°F (135°C)

b) Heat unaged asphalt binder until fluid enough to pour. Stir the sample, being careful not to entrap air bubbles

c) Pour appropriate amount of asphalt binder into sample chamber. The sample size varies according to the selected spindle

d) Insert sample chamber into RV temperature controller unit and carefully lower spindle into sample

e) Bring sample to the desired test temperature (typically 275°F (135°C)) within approximately 30 minutes and allow it to equilibrate

f) Rotate spindle at 20 RPM

g) Once the sample has reached temperature and equilibrated, take 3 viscosity readings from RV display, allowing 1 minute between each reading. Viscosity (dynamic/absolute) is reported as the average of 3 readings

h) The test takes 1.5 hours

Rotational Viscometer (RV) ASTM D 4402

The basic RV test measures the torque required to maintain a constant rotational speed (20 RPM) of a cylindrical spindle while submerged in an asphalt binder at a constant temperature (typically 275°F (135°C)).

This torque (proportional to viscosity) is then converted to a viscosity and displayed automatically by the RV.

Typical Values:

o RV viscosities depend upon the material measured and the test temperature.

o Super Pave testing is done at 275°F (135°C) and typical dynamic viscosity values for asphalt binders at this temperature are 0.2 to 2 Pa·s.

o The AI recommends using a value of about 0.28 Pa·s for compaction temperatures.

o at high in-service pavement temperatures (e.g., on a hot summer day of 140°F (60°C)) dynamic viscosity can be around 200 Pa·s.

▪ Typical Values:

o Some representative dynamic viscosities are:

o PG 64-22 asphalt binder at 275°F (135°C) ≈ 0.570 Pa·s

o PG 76-22 asphalt binder at 275°F (135°C) ≈ 1.800 Pa·s

o Water at room temperature = 0.001 Pa·s

o Motor oil at room temperature = 0.088 Pa·s

o Liquid Honey at room temperature = 2 Pa·s

o Mayonnaise at room temperature = 5 Pa·s

3. Dynamic Shear Rheometer (DSR) AASHTO T 315

ASTM D4402 AASHTO M320-10 AASHTO T315-12 AASHTO M332-14 AASHTO T350-14 AASHTO TP 70 ASTM D7405-10A EN 14770 ASTM D7175-08 ASTM D4402 M

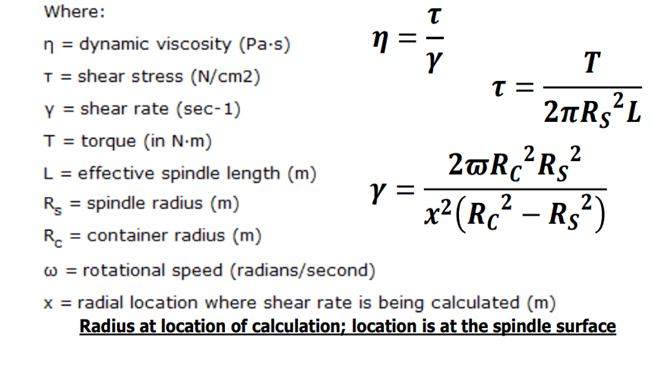

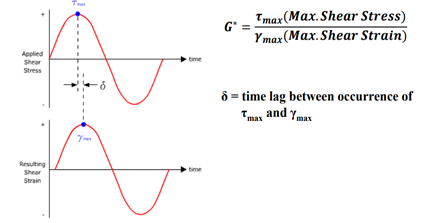

▪ The DSR is used to characterize the viscous and elastic behavior of asphalt binders at medium (fatigue cracking) to high temperatures (rutting).

▪ Asphalt binders are viscoelastic. This means they behave partly like an elastic solid (deformation due to loading is recoverable – it is able to return to its original shape after a load is removed) and partly like a viscous liquid (deformation due to loading is nonrecoverable – it cannot return to its original shape after a load is removed).

Dynamic Shear Rheometer (DSR) AASHTO T 315

a) Heat the asphalt binder until the binder is sufficiently fluid to pour the test specimens.

b) Heat the DSR to the test temperature. This preheats the upper and lower plates, which allows the specimen to adhere to them.

c) Place the asphalt binder sample between the test plates.

d) Put the test plates just in contact.

e) Trim the excess material.

f) Bring the specimen to the test temperature. Start the test only after the specimen has been at the desired temperature for at least 10 minutes.

g) The DSR conditions the specimen for 10 cycles at a frequency of 10 rad/sec (1.59Hz).

h) The DSR takes test measurements over the next 10 cycles and then the software reduces the data to produce a value for G* and δ

▪Rutting Prevention: In order to resist rutting, an asphalt binder should be stiff (it should not deform too much) and it should be elastic (it should be able to return to its original shape after load deformation). Therefore, the complex shear modulus elastic portion, G*/sinδ, should be maximized.

▪ Fatigue Cracking Prevention: In order to resist fatigue cracking, an asphalt binder should be elastic (able to rebound and not cracking) but not too stiff (excessively stiff substances will crack rather than deform-then-rebound). Therefore, the complex shear modulus viscous portion, G*sinδ, should be minimized.

▪ The basic DSR test uses a thin asphalt binder sample sandwiched between two circular plates. The lower plate is fixed while the upper plate oscillates back and forth across the sample at 10 rad/sec (1.59 Hz; 55 mph) to create a shearing action.

▪ DSR tests are conducted on unaged, RTFO aged and PAV aged asphalt binder samples.

▪ The larger the phase angle (δ), the more viscous the material is.

o Purely elastic material: δ = 0 degrees

o Purely viscous material: δ = 90 degrees

▪ G* and δ are used as predictors of HMA rutting and fatigue cracking. Early in pavement life to mid-life rutting is the main concern (on unaged and RTFO aged samples), while later in pavement life fatigue cracking becomes the major concern (PAV aged samples).

4. Rolling Thin Film Oven (RTFO)

AASHTO T 240 and ASTM D 2872

The Rolling Thin-Film Oven (RTFO) provides simulated short term aged asphalt binder for physical property testing. Asphalt binder is exposed to elevated temperatures to simulate manufacturing and placement aging. The RTFO also provides a quantitative measure of the volatiles lost during the aging process.

The basic RTFO procedure takes unaged asphalt binder samples in cylindrical glass bottles and places these bottles in a rotating carriage within an oven. The carriage rotates within the oven while the 325°F (163°C) temperature ages the samples for 85 minutes. Samples are then stored for use in physical properties tests or the PAV. The standard Rolling Thin-Film Oven test is:

• AASHTO T 240 and ASTM D 2872.

- Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test)

Basic Procedure

- Heat a sample of asphalt binder until it is fluid to pour. Stir sample to ensure homogeneity and remove air bubbles.

2- If a determination of mass change is desired, label two RTFO bottles and weigh them empty. These are designated as the “mass change” bottles. Record the weights.

3-Pour 1.23 oz (35 g) of asphalt binder into each bottle Immediately after pouring each bottle, turn the bottles on their side without rotating or twisting and place them on a cooling rack.

4-Allow all bottles to cool 60 to 180 minutes.

5-After cooling, weigh the two mass change bottles again. Record the weights.

6-Place the bottles in the RTFO oven carousel close the door, and rotate the carousel at 15 RPM for 85 minutes.

During this time, maintain the oven temperature at 325°F (163°C) and the airflow into the bottles at 244 in3/min (4000 ml/min).

6-Remove the bottles one at a time from the carousel, setting the mass change bottles aside. Residue from the remaining bottles should be transferred to a single container. Remove residue from each bottle by first pouring as much material as possible, then scraping the sides of the bottle to remove any remaining residue. There is no standard scraping utensil but at least 90 percent of the asphalt binder should be removed from the bottle. RTFO residue should be tested within 72 hours of aging.

7-After cooling the two mass change bottles for 60 – 180 minutes, weigh them and discard their residue. Record the weights.

5. Bending Beam Rheometer (BBR) AASHTO T 313

ASTM D6648 AASHTO T313 EN 14771

▪ As surrounding temperatures drop, pavements contract and build up internal stresses. If this contraction occurs fast enough the pavement may crack because it does not have time to relax these stresses.

▪ This type of crack, typically called a “thermal crack” or transverse crack, can result from either of two mechanisms: a) Single thermal cycle below the critical temperature. A single severe drop in temperature causes stress to build up to a critical point that causes cracking quickly.

▪ This type of crack, typically called a “thermal crack” or transverse crack, can result from either of two mechanisms: b) Multiple thermal cycles above the critical temperature. Repeated thermal contraction and expansion above the critical temperature can cause stresses to build up and eventually cause cracking.

The BBR is a test designed to measure the AC ‘s resistance to these thermal stresses (stiffness) and the stress relaxation rate. Asphalt binders that are not too stiff at low temperatures and able to relax built-up stresses are desirable.

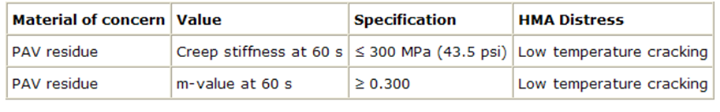

▪ Because low-temperature cracking is a phenomenon found mostly in older pavements, the test is run on PAV aged samples.

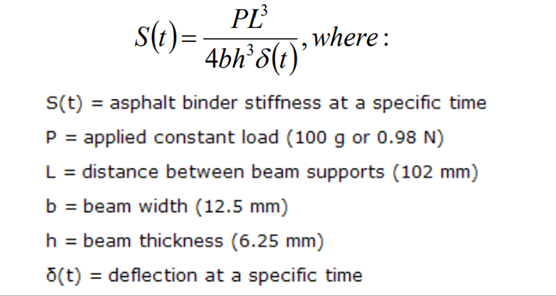

▪ A sample of asphalt binder is molded into a beam measuring 6.25 ´ 12.5 ´ 127 mm.

▪ This sample is then simply supported at two points 102 mm apart in a controlled temperature fluid bath.

▪ The beam is then loaded at the midpoint by a 100 g load = 0.98 N of force.

▪ The beam deflection is measured at 8, 15, 30, 60, 120 and 240 seconds.

▪ Beam stiffness (flexural creep stiffness), is calculated for these times.

▪ Creep stiffness is a measure of thermal stresses. A higher creep stiffness value indicates higher thermal stresses.

▪ Beam stiffness (flexural creep stiffness)

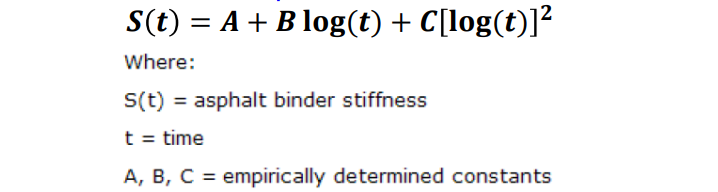

In order to determine the stress relaxation properties of an asphalt binder, creep stiffness calculations are made at 8, 15, 30, 60, 120 and 240 seconds of loading.

▪ A curve, called the stiffness master curve, is then fitted to these points and is of the form:

▪ The slope of this master stiffness curve at 60 seconds, designated by the letter “m-value”, is a measure of the rate at which the asphalt binder relieves stress.

▪ A lower m-value indicates a lesser ability to relax stresses.

▪Bending Beam Rheometer (BBR) AASHTO T 313

a) Set the BBR fluid bath to the desired test temperature.

b) Heat the PAV aged asphalt binder until fluid enough to pour.

c) Stir the heated sample to remove air bubbles and pour into two aluminum BBR molds. d) Allow molds to cool, then trim the top of sample flush with mold.

e) Demold samples.

f) Place beams in the BBR bath at test temperature for 60 minutes to condition them.

g) Place the test beam on the test supports.

h) Apply the 0.98 N test load and maintain the load constant for 240 seconds. During this period, readings of deflection over time are recorded.

I) Repeat for the second beam.

Approximate test time is 3 hours (from sample preparation to end of test)

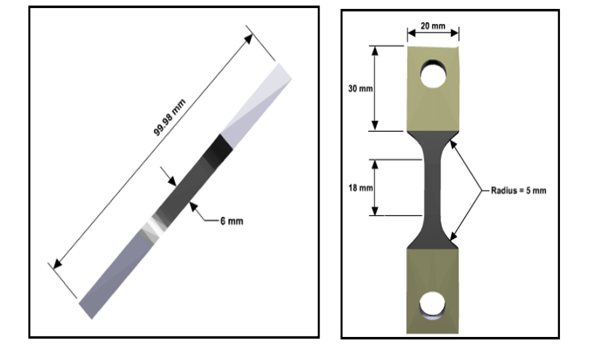

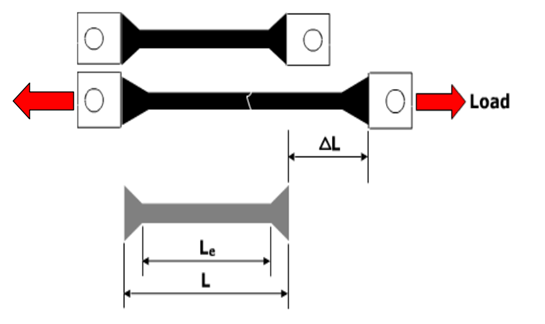

6. Direct Tension Tester (DTT) AASHTO T 314

EN 12697-26 ANNEX E EN 12697-26 ANNEX D AASHTO TP 107-14

▪ There is a good relationship between the stiffness of ACs and the amount of stretching (ductility) they undergo before breaking at low temperatures.

▪ The DTT was developed to address stiff, ductile asphalt binders (cannot be addressed by the BBR). Ex. Modified asphalts.

▪ The DTT is used when the BBR creep stiffness is between 300 and 600 MPa at low pavement service temperatures.

▪ Below 300 MPa the DTT need not be used because the BBR would be adequate.

▪ The DTT test provides a measure of low-temperature stiffness and relaxation properties of asphalt binders. These parameters indicate an asphalt binder’s ability to resist low-temperature cracking.

▪ Because low-temperature cracking is a phenomenon found mostly in older pavements, the test is run on PAV aged samples at low temperatures

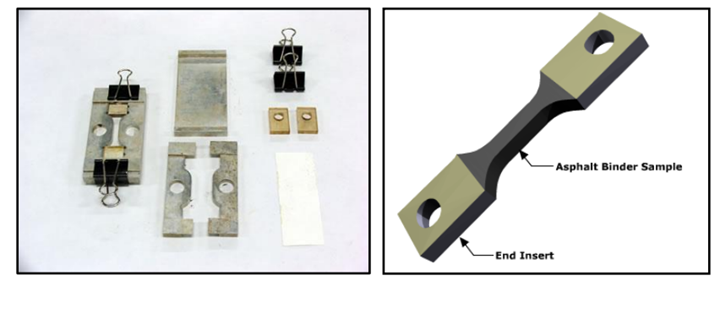

▪The basic DTT test measures the stress and strain at failure of a specimen of asphalt binder pulled apart at a constant rate of elongation.

▪ Failure identification:

- Fracture, failure strain is defined as the strain at the moment of fracture.

- Flow without fracture, failure strain is defined as the strain corresponding to the maximum stress observed. The test should not be continued past 10 percent strain; if the sample has not failed by 10 percent strain, record failure strain as “greater than 10 percent”.

▪ Failure location: Ideally failure should occur in the gage section. If failure occurs in the throat section, note and record this occurrence.

Direct Tension Tester (DTT) AASHTO T 314

Procedure:

a) Heat PAV aged asphalt binder until fluid to pour. Stir to ensure homogeneity.

b) Pour the heated sample into two DTT molds.

c) Allow molds to cool for 30 – 60 minutes at room temperature, then trim the top of sample flush with mold.

d) Demold sample.

e) Apply 0.45 lb (2 N) pulling force.

f) Set the strain rate to 1 mm/min.

g) Test temperature is in the 0 to − 36 °C range. h) Test a total of 6 samples as described above to ensure repeatability.

References

pavement interactive. (2015). Retrieved from pavement: https://pavementinteractive.org/

Corbett, L.W. and Merz, R.E. (1975). Asphalt Binder Hardening in the Michigan Test Road After 18 Years of Service. Transportation Research Record 544. Transportation Research Board, National Research Council, Washington, D.C. pp. 27-34.↵

Roberts, F.L.; Kandhal, P.S.; Brown, E.R.; Lee, D.Y. and Kennedy, T.W. (1996). Hot Mix Asphalt Materials, Mixture Design, and Construction. National Asphalt Pavement Association Education Foundation. Lanham, MD